Commercial Sheet Metal Roll Former

Available in standard 24 or 26 gauge.

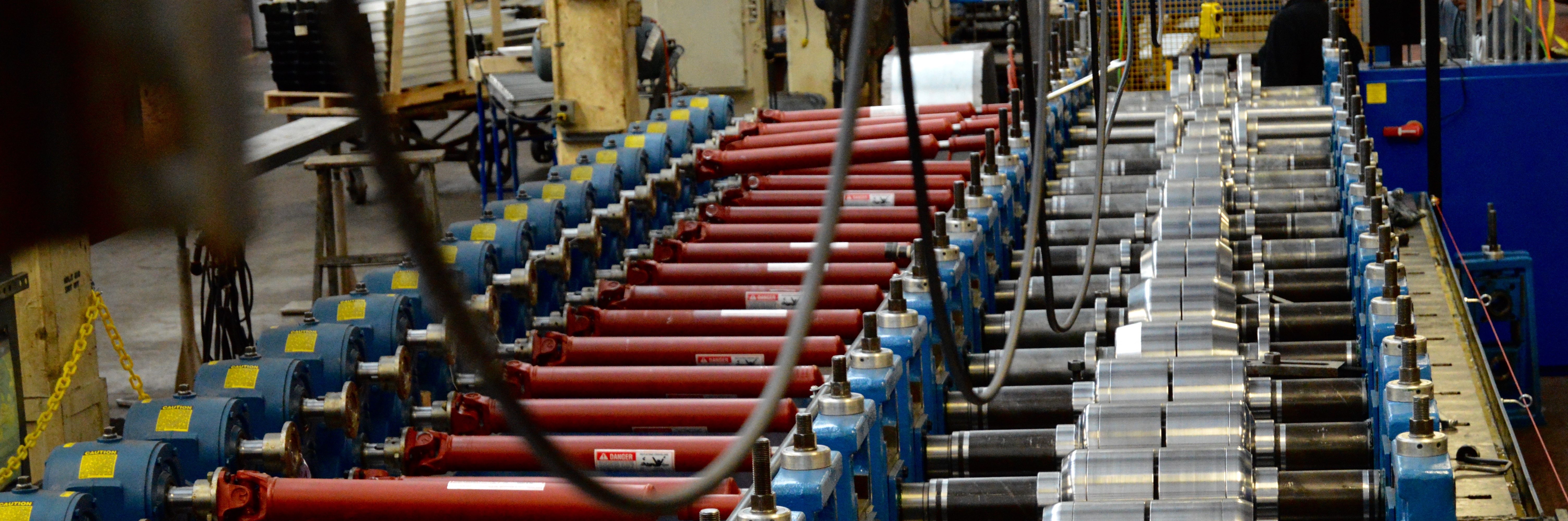

Commercial sheet metal roll former. Roll forming machine for sale. We can also produce tooling to meet custom roll forming specifications for commercial products including specialty products like trucks and trailers. Machine forms 1 3 4 snap lock 2 and 1 1 2 mechanically seamed profiles. Roll forming is used to create very long sheet metal parts with typical widths of 1 20 inches and thicknesses of 0 004 0 125 inches.

Each standard or custom roll forming machine for sale comes with a 1 year warranty for parts and labor plus tech support from our headquarters in orlando fl. Roll forming machines llc is the leading supplier among roll forming companies world wide since 2009. Independent drive system is always centered on the panel coupled with free spinning forming rollers minimizes oil canning and potential adjustments. Roll forming has many cost advantages over brake forming and preformed panels.

Since 1978 we have been leading the industry with our innovation and service. Manual crimper bead beader sheet metal roll roller former fabrication 24 gauge. Wide and 0 25 inches thick. Roll formed parts roll formed shapes omco has developed tooling for basic sheet metal roll forming shapes that are common in many industries.

However wider and thicker sheets can be formed some up to 5 ft. We also buy your used machinery from a single machine to entire shops. Examples of the types of roll forming shapes we produce. Cpm offers a wide variety of used sheet metal brakes sheet metal roll forming machines sheet metal shears and much more.

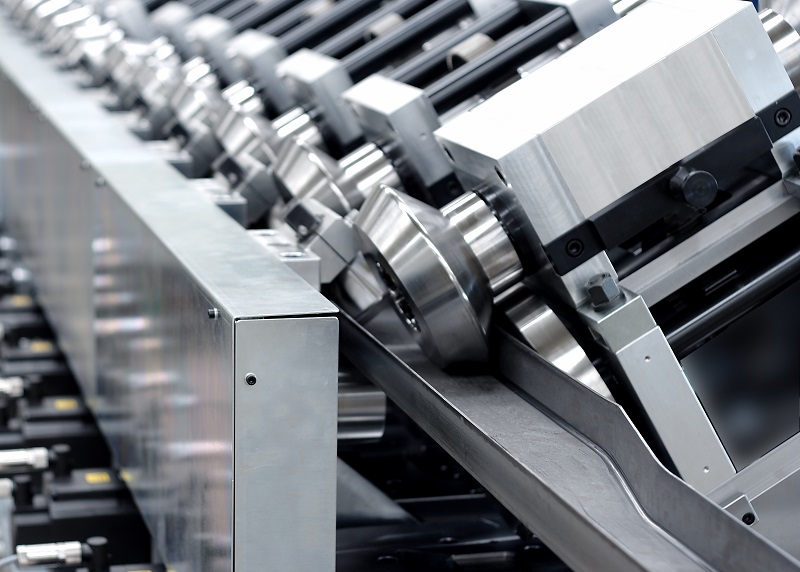

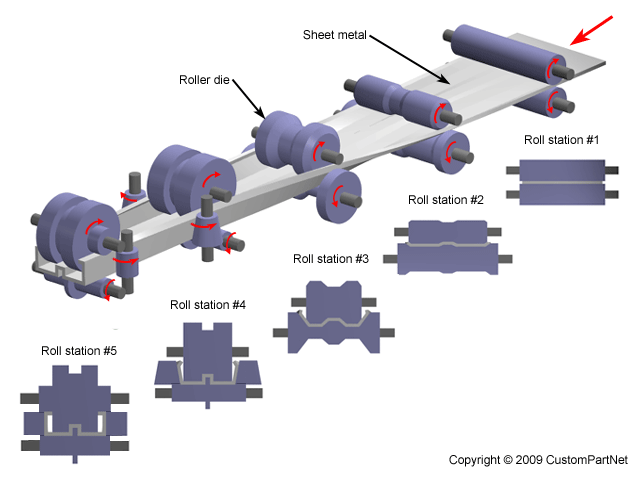

Roll formers work by forcing metal through a series of horizontal rotating rollers or roller dies. Let metal mart be your supplier for all your portable roll former panel coil and trim stock needs. Please call us today at 407 859 1119 or e mail us for a free consultation and quote with the leader. Contact us today for all of your sheet metal needs.

Roll former corporation offers the most productive and cost effective roll forming equipment for the metal roofing and architectural sheet metal industries. Bradbury has supplied multi profile trim rollformers to the metal building industry for more than 50 years. The roll forming process is capable of producing parts with tolerances as tight as 0 005 inches. 320mm 12 slip roll roller sheet metal fabrication brass copper 1mm thickness.

Ul580 class 90 panels. Make offer manual crimper bead beader sheet metal roll roller former fabrication 24 gauge. Feed metal to rollers. At the beginning of a roll forming process manufacturers feed a stock of metal into the first roller die set.

These roller die series help them produce a uniform and constant cross section profile.